Understanding Splinting Materials in Occupational Therapy

Splinting is a vital skill in occupational therapy, particularly in managing injuries and aiding rehabilitation. Various splinting materials are used to customize each intervention based on individual patient needs.

The Importance of Understanding Tissue Healing

Successful orthotic intervention aligns closely with the phases of tissue healing. Let’s break down the major phases and their impact on splinting:

- Acute Inflammatory Phase: Employ orthoses to provide immobilization and support.

- Proliferative Phase: Start active motion under protection, modifying orthoses as needed.

- Maturation Phase: Increase movement and resistance, using mobilization orthoses to combat stiffness.

In our full guide, we explore detailed case examples and quizzes for each phase.

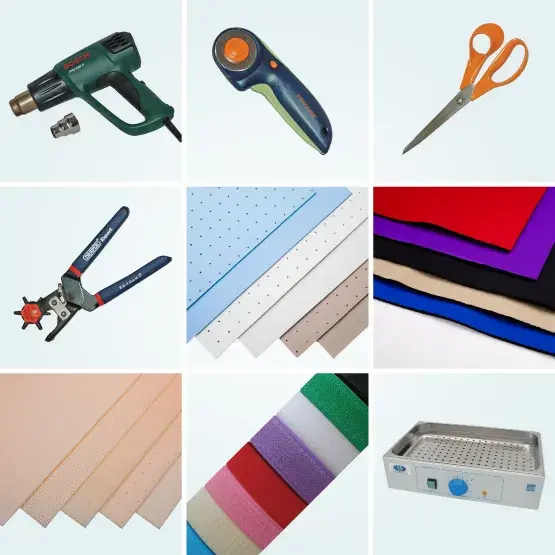

Low-Temperature Thermoplastics: The Go-to for Moldable Splint Materials

Low-temperature thermoplastic (LTT) is the most common moldable splinting material due to its ease of use and adaptability. Heated between 135° and 180°F, these materials can be safely placed against the skin and molded efficiently.

Thermoplastic Options in Splinting

There are several options when it comes to selecting thermoplastics for splinting in occupational therapy:

- Thickness: Varies depending on the support needed.

- Solid vs. Perforations: Choose based on the required breathability and weight considerations.

- Bonding – Uncoated vs. Coated: Dictates the type of surface preparation needed.

- Conformability vs. Resistance: Affects how the material handles and molds.

Explore our member content for a deeper understanding of each option.

Characteristics of Splinting Material

| Property/Characteristic | What it Means | Intended Use |

|---|---|---|

| Rigidity | How strong and resistant the material is to stress. | Essential for large splints and high-force requirements. |

| Memory | The ability to return to original shape after being reformed. | Useful for reshaping splints frequently. |

| Conformability/Drapability | Ease with which the material fits to the body. | Best with gentle handling for intricate areas. |

| Resistance to Stretch | Degree of control during stretching when heated. | Helpful for splints requiring firm handling. |

| Coating | The necessity of surface preparation for joining pieces. | Differences between uncoated (permanent bonding) and coated (temporary bonding). |

| Perforations | Allow air circulation and reduced weight. | Avoid stretching to prevent compromising material strength. |

In our full guide, you will find a detailed examination of each of these features, including quizzes to test your understanding.

Safety First in Orthotic Fabrication

When fabricating orthoses, safety is paramount due to the use of heat and sharp tools.

- Never leave tools unattended.

- Always check the temperature of materials before application.

- Monitor material shrinkage to prevent injury.

Ensuring Compliance with Orthoses

A well-made orthosis depends on its proper use as instructed:

- Educate patients on benefits and risks.

- Define permissible activities during wear.

- Maintain ongoing check-ins to ensure comfort and fit.

- Document and outline the wearing schedule.

Engage patients by allowing them choices in color or design and having them keep schedule records to boost adherence.

Want detailed practice tips to ace the NBCOT® exam? Join now for full access!

What are the most common splinting materials used in occupational therapy?

The most common splinting materials used in occupational therapy are low-temperature thermoplastics due to their ease of use and adaptability. These materials are heated between 135° and 180°F to become moldable against the skin.

How do tissue healing phases impact the use of orthoses?

Orthotic interventions should align with the tissue healing phases. During the Acute Inflammatory Phase, orthoses provide immobilization and support. In the Proliferative Phase, active motion is initiated under protection. During the Maturation Phase, increased movement and resistance are encouraged with mobilization orthoses.

What considerations should be made when selecting thermoplastic materials for splinting?

When selecting thermoplastics, consider thickness for support, solid versus perforations for breathability, bonding needs for surface preparation, and conformability versus resistance for how the material molds and handles.

What safety measures are crucial during orthotic fabrication?

Safety measures include never leaving tools unattended, checking material temperatures before application, and monitoring material shrinkage to prevent injury.

How can patients be encouraged to comply with wearing orthoses?

Educate patients on the benefits and risks of orthoses, outline permissible activities, check for comfort and fit regularly, and engage them with choices in color or design. Document and outline a wearing schedule to boost adherence.